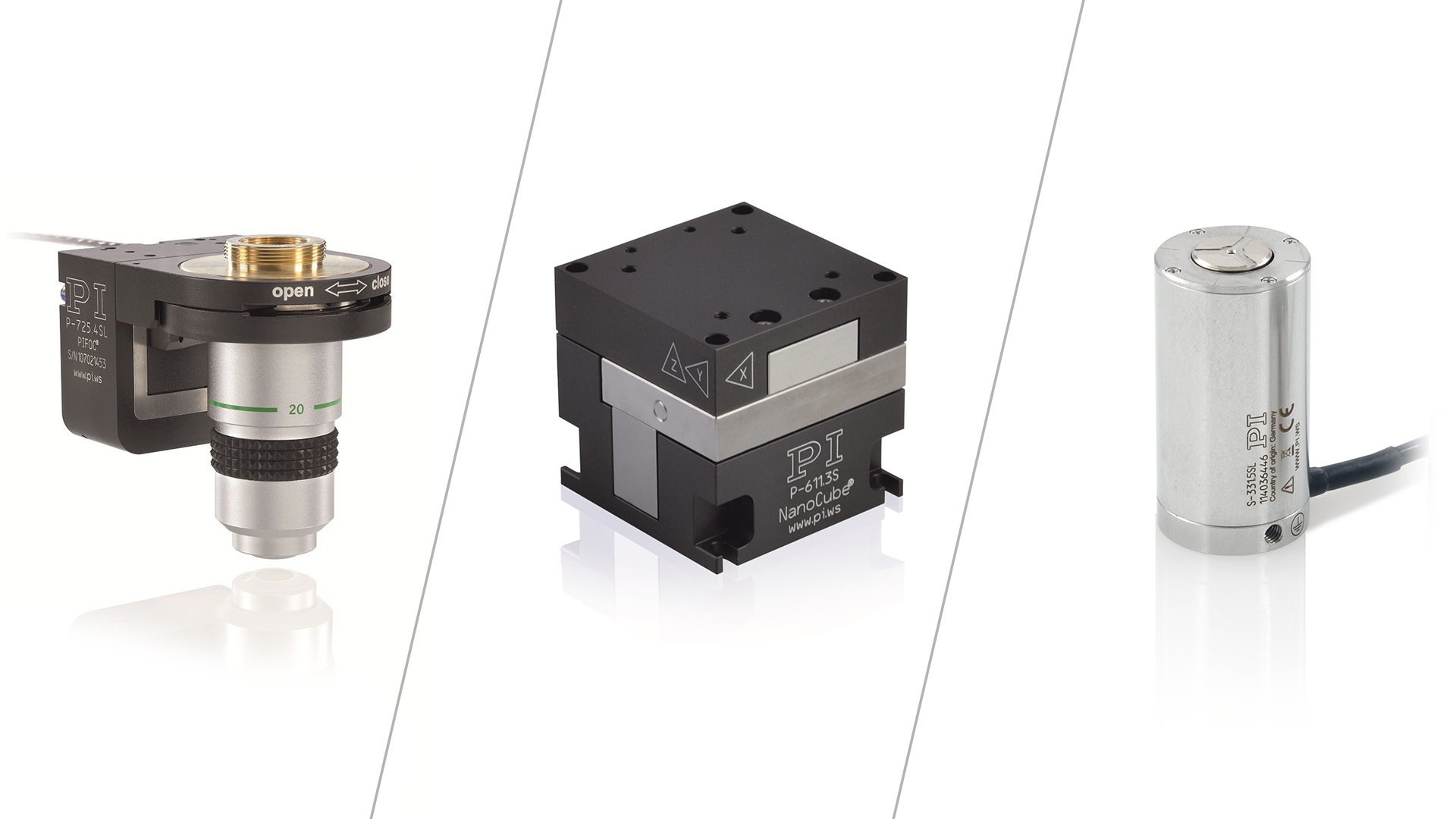

Currently, one of the design issues is how to solve the. The CP1XY offers ☐.25 mm of XY travel manipulated by M2.5 x 0.20 fine pitch adjusters. The actuators can achieve a bidirectional repeatability of 5.0 m. Thorlabs' 6-Axis NanoMax Stages with stepper motor actuators provide 4 mm (0.16') of X, Y, and Z travel and 6 (105 mrad) of x, y, z (Roll, Pitch, and Yaw) travel. Lots of other flexure-based translational micropositioning stages have been reported in 9, 10, 11. Preconfigured with DRV208 Stepper Motor Actuators for Automated Alignments. Xu has designed a novel flexure-based XY precision positioning system 8 by using compound leaf flexures. The analysis and design of general platform type parallel mechanisms containing flexure joints. The latest generation of digital controllers, also further enhances the bandwidth, linearity, and the position stability as well as step-and-settle times. The modules can achieve a stroke of 142 m with a high precision. This allows engineers to provide motion in desired directions, but constraint in other directions. A flexural mechanism generates relative motion between fixed support. The arrangment of beams can be designed to be compliant in its degree (s) of freedom (DOF), but relatively stiff in its degree (s) of constraint (DOC). Planer XY Flexurel Mechanisms has various applications in precision motion mechanisms. Most of PI's XY piezo stages are equipped with an ID chip that contains calibration data for the digital piezo controller, allowing stage an controller to be swapped in the field without the need for recalibration. Flexures are bearings that allow motion by bending load elements such as beams. Stacked or nested X-Y stage axis designs are also available – they trade the flexibility of modularity with the added inertia/height and lower dynamic performance.įrictionless XY-Motion with Nanometer Precisionĭue to the frictionless design of drive system (solid-state piezo stack actuators), sensors, and the flexure-based guiding system, PI piezo nanopositioning stages can provide sub-nanometer positioning resolution. For the highest performance and optimized dynamics, a monolithic planar design (single module) with parallel kinematics and parallel metrology position feedback is recommended. Wire EDM (Electric Discharge Machining) cut flexures provide the best guiding accuracy. The name of this structure is influenced by its proximity to the liver the word hepatic comes from hpar, which means liver in Greek. XY piezo stages can be designed in several ways. The hepatic flexure, also known as the right colic flexure, is found in the digestive system of the human body and creates the bend in the colon that connects the ascending colon and the transverse colon.

0 kommentar(er)

0 kommentar(er)